Single wall round flue system T600

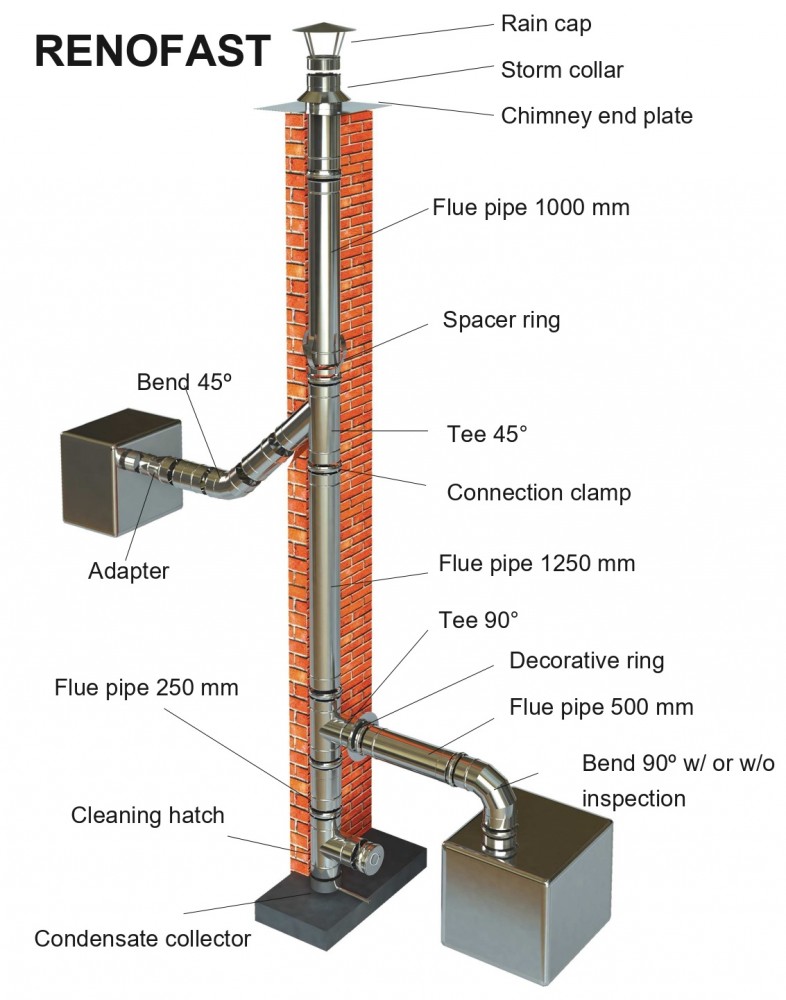

Round Single-Wall Chimneys RENOFAST

Single-wall round chimney systems are the fundamental element of modern chimney technology. They are used for connecting heating appliances to the main chimney, creating ventilation ducts, and for lining (relining) existing brick shafts.

SIA Akvilon manufactures RENOFAST 200, RENOFAST 600, and RENOFAST 600 Plus systems at its own production facility in Riga. We use industrial laser and plasma metal cutting, as well as robotic TIG welding. Thanks to the socket connection system, assembly is fast and precise. All elements are certified according to the European standard EN 1856-2 and correspond to temperature class T200 and T600.

Advantages of buying from us

- Direct from the manufacturer: You work directly with us, receiving a fair price without intermediary markups.

- In stock: We maintain a constant stock of key items. You don’t need to wait for weeks — you can come and purchase immediately.

- Convenient logistics: Arrange fast delivery (across Latvia and the EU) or pick up your order from our warehouse in Riga.

- Standard EN 1856-2: The CE marking confirms that the products have undergone factory production control and are safe for operation.

If you require installation, we also provide professional chimney lining services.

Advantages of the Round Section

The round shape of the pipe is optimal for smoke extraction from an aerodynamic perspective:

- Efficient Draft: Flue gases move in a spiral as they rise. In a round channel, the flow meets no resistance from corners, minimizing turbulence.

- Clean Channel: The absence of corners prevents the formation of stagnant zones where soot usually accumulates. Smooth walls and a round shape significantly simplify the mechanical cleaning process.

- Structural Rigidity: A round pipe possesses natural geometric rigidity, making it resistant to thermal deformations.

Materials: Which Steel Grade to Choose?

The durability of the system directly depends on matching the steel grade to the operating conditions. We offer three versions:

RENOFAST 600 (AISI 304 / 304L)

The base solution made of classic chromium-nickel stainless steel. The main stock standard.

- Application: Pellet (granule) boilers (optimal choice), wood stoves, fireplaces, sauna heaters, gas boilers, ventilation.

- Properties: The steel possesses high heat resistance and excellent corrosion resistance in the environment created by burning pellets and wood.

RENOFAST 600 Plus (AISI 316L)

Acid-resistant execution. The steel is alloyed with molybdenum (2-3%), which enhances its chemical resistance.

- Application: Diesel boilers, specific industrial facilities, systems with high condensate acidity.

- Properties: Molybdenum ensures the metal's resistance to aggressive acids. Recommended for liquid fuel equipment.

RENOFAST T200 (With Seals)

A specialized airtight system, elements of which are equipped with grooves for heat-resistant silicone rings.

- Application: Modern gas and condensing boilers working under positive pressure.

- Properties: The presence of seals ensures the highest gas tightness class (P1) and guarantees 100% protection against condensate leaks even under pressure.

Technical Specifications

| Parameter | RENOFAST 600 | RENOFAST 600 Plus | RENOFAST T200 |

|---|---|---|---|

| Material | Stainless Steel AISI 304/304L | Stainless Steel AISI 316L | Stainless Steel AISI 304 |

| Wall Thickness | 0.5 / 0.6 / 0.8 / 1.0 mm | 0.5 / 0.6 mm | |

| Working Temperature | T600 (up to 600°C) | T200 (up to 200°C) | |

| Connection Type | Socket, no gaskets | Socket + Seal | |

| Seam Welding | Robotic seam TIG welding | ||

Important Installation Aspects

"Condensate" Assembly

The socket design implies assembly where the upper pipe is inserted into the lower one. This is critical: condensate must flow down the inner wall of the pipe without entering the joints or the outer surface of the chimney.

Connecting to Ceramic Chimneys

When connecting a metal pipe to a ceramic shaft inlet (Schiedel, Tona, etc.), a special adapter with a soft seal must be used. Direct embedding of metal into ceramic using cement or rigid sealants is prohibited — thermal expansion of the steel can lead to the destruction of the ceramic tee.

Fire Safety

A single-wall pipe is a source of thermal radiation. During installation, safe distances to combustible structures (wood, drywall, wallpaper) must be observed — at least 500 mm. For outdoor installation and passing through ceilings/roofs, double-wall insulated chimneys should be used.

Diameter Calculation

The chimney diameter is selected based on the boiler power and pipe height. It is not recommended to narrow the chimney cross-section relative to the heating appliance outlet without a preliminary aerodynamic calculation.